Unlocking the Potential of Microalgae - Photobioreactor Decarbonation Breakthrough

NeoCarbons’ patented technology: Recycling CO2 into Biochemicals

Disruptive Photobioreactor for industrial microalgae photosynthesis

Disruptive Photobioreactor for industrial microalgae photosynthesis

Headquartered in Switzerland and leveraging the research and development capabilities of leading laboratories, NeoCarbons proposes competitive scalable solutions for the decarbonation of food, feeds, fine chemicals (pharma, cosmeto, fragrances etc.) and chemicals ( fuels, pesticides, fertilizers etc.) industries.

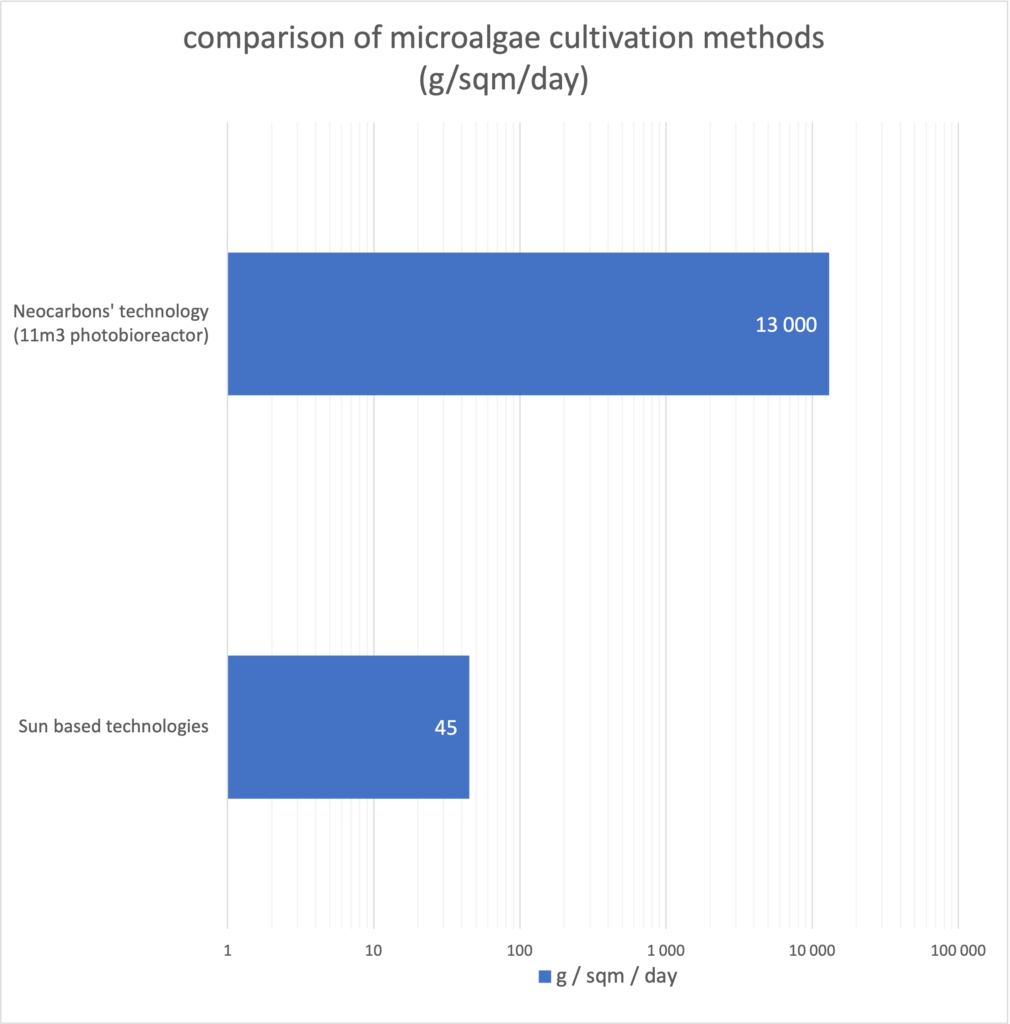

With focused research objectives, we have developed a unique know-how to precisely control and optimize the development cycle of microalgae within our photobioreactor, in continuous industrial production mode. The technology is successfully validated as groundbreaking.

Our Technology

Go to Section

Investors & Partnerships

Go to Section

About Us & Roadmap

Go to Section

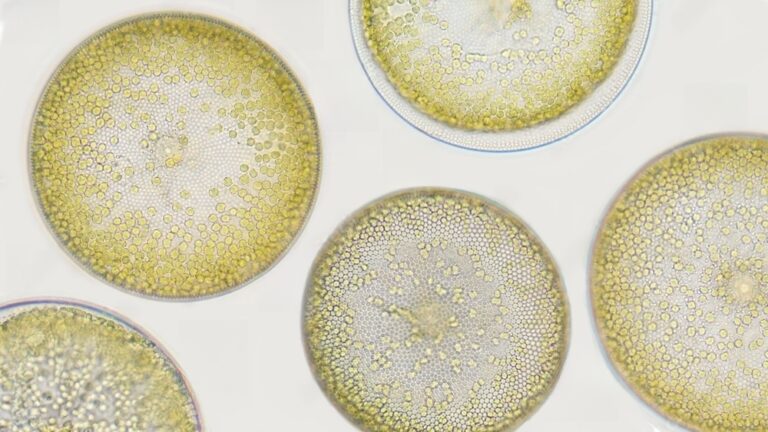

Learn About Micro algae

Go to SectionDecarbonated 2030's: Our Unique Contribution

We consider CO2 to be the raw material of the 21st century.

However, technologies to recycle it into valuable bio and green chemicals currently fall short of being productive and competitive.

This is why we have designed and validated our equipment: high productivity to serve buoyant demand, low cost for being competitive against fossil based value chains, and constant quality not influenced by weather and/or localization.

Harnessing microalgae grown in our fully controlled photobioreactors for bio and green chemicals production presents a comparatively net negative CO2 balance with minimal environmental impact.

Neocarbons equipment enables microalgae to unleash their full potential as a key supply chain for alternative proteins, green and bio chemicals.

Productivity and constant quality: key benefits for our clients

- Energy transfer inside the photobioreactor drives daily productivity, quality and production costs. This is NeoCarbons’ proprietary knowledge

- Reach over 10x g/l concentration, tested on major microalgae strains including cyanobacteria

- Significantly higher production of high value-added bio chemicals (proteins, pigments, fine chemicals and precursors)

- CPU controlled process for industrially compatible high through- put continuous operations

- Compatible with chemical and thermal sterilization process

Our Certifications

US & EU Patent

ZHAW - Industrial Micro algae Processes

Swiss Innovation Challenge